To be the most trusted and innovative provider of high-quality, sustainable packaging solutions, delivering excellence through precision, reliability, and customer-focused service.

At Issa Wood Industries, we envision a future where packaging not only protects products but also preserves the planet through cutting-edge technology, responsible sourcing, and a commitment to global standards.

Laying The Foundation

Our Director, Mr. Inasu Joseph, began his career at Raja & Co., a leading wooden packaging manufacturer in Thrissur, Kerala, where he played a key role in expanding the clientele, securing major clients like Asian Bearing & Mill Stores, Karnataka Ball Bearing Corporation Ltd, Premier Mills, Fuji Umbrella, and Futura Polymers.

Expanding Market Presence

Recognizing his expertise, Mr. Inasu Joseph became a partner at Raja & Co., leading the establishment of a Bangalore unit. Under his guidance, the company dominated the beverage packaging industry, serving as the exclusive supplier to Coca-Cola, PepsiCo, Bacardi, and Nestlé.

Diversification & Specialization

Mr. Joseph founded Raja Pallet in Bangalore to expand into precision packaging. The company quickly earned a reputation for quality, supplying industry leaders like Tata Advanced Systems, Proceal, Kionix, and Millipore Sigma.

Establishing A Strong Legacy

In 2010, Mr. Joseph launched Raja Spools in Jigani, Bangalore, with Lapp India as its primary client. Over time, the company grew significantly, serving 16+ niche industries and building a strong reputation for excellence and reliability.

Uniting Under Issa Wood Industries

To unify decades of expertise, all units merged into a single brand called Issa Wood Industries. Today, we lead the industry with innovative wooden packaging, superior quality, and a customer-first approach.

Our Director, Mr. Inasu Joseph, began his career at Raja & Co., a leading wooden packaging manufacturer in Thrissur, Kerala, where he played a key role in expanding the clientele, securing major clients like Asian Bearing & Mill Stores, Karnataka Ball Bearing Corporation Ltd, Premier Mills, Fuji Umbrella, and Futura Polymers.

Recognizing his expertise, Mr. Inasu Joseph became a partner at Raja & Co., leading the establishment of a Bangalore unit. Under his guidance, the company dominated the beverage packaging industry, serving as the exclusive supplier to Coca-Cola, PepsiCo, Bacardi, and Nestlé.

Mr. Joseph founded Raja Pallet in Bangalore to expand into precision packaging. The company quickly earned a reputation for quality, supplying industry leaders like Tata Advanced Systems, Proceal, Kionix, and Millipore Sigma.

In 2010, Mr. Joseph launched Raja Spools in Jigani, Bangalore, with Lapp India as its primary client. Over time, the company grew significantly, serving 16+ niche industries and building a strong reputation for excellence and reliability

To unify decades of expertise, all units merged into a single brand called Issa Wood Industries. Today, we lead the industry with innovative wooden packaging, superior quality, and a customer-first approach.

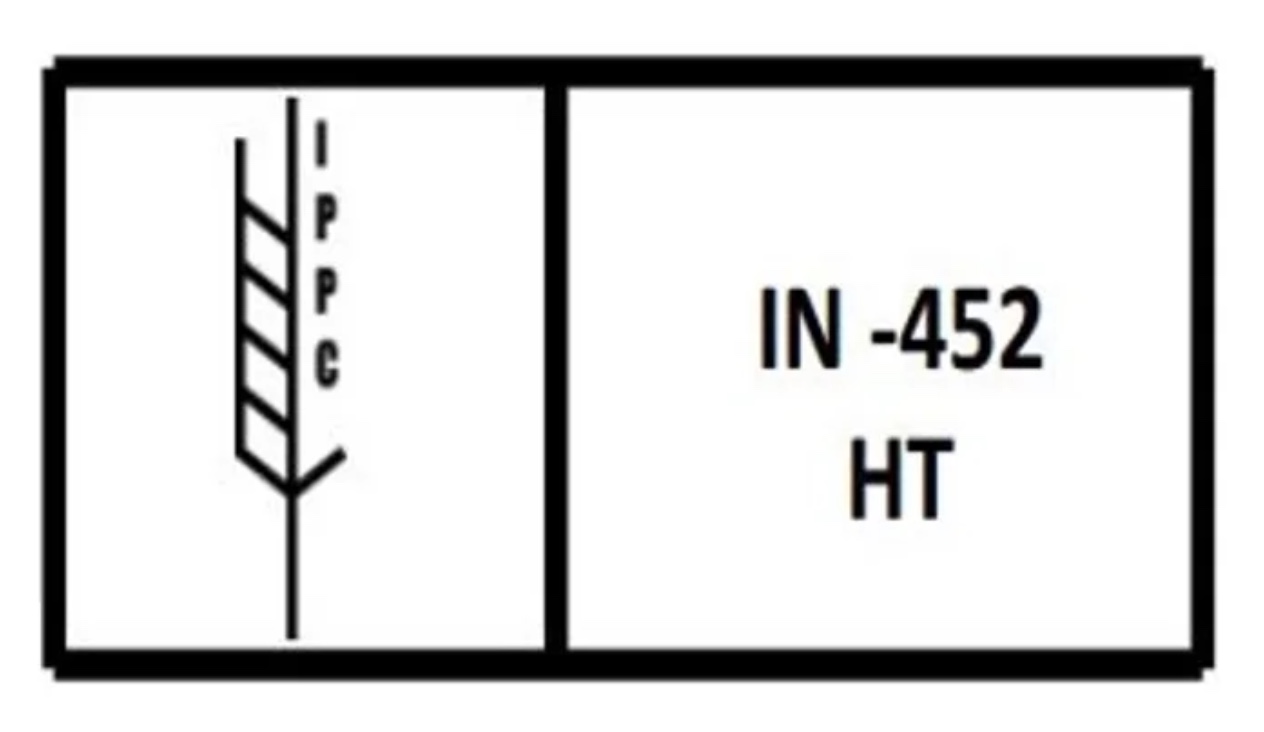

ISPM-15 CERTIFIED FHAT

Our manufacturing facility features an in-house ISPM-15 Certified FHAT (Forced Hot Air Treatment) plant, ensuring compliance with International Plant Protection Convention (IPPC) standards. This system uses controlled hot air circulation to eliminate pests, larvae, and fungi, raising the wood's core temperature to 56°C for at least 30 minutes, as required by ISPM-15 regulations. Each treated unit is stamped and certified for seamless global export.

Unlike chemical fumigation, our FHAT process is eco-friendly and non-toxic, aligning with our commitment to sustainability and responsible sourcing. With this advanced in-house treatment, we guarantee high-quality, pest-free, and globally compliant wood packaging for secure international shipping.

HAVE A REQUIREMENT?

Looking for reliable wooden packaging solutions? Let's build something great together!

Get In Touch!